Digitale Produktionssteuerung in Echtzeit

MES System - Transparenz, Steuerung und Effizienz in der Produktion.

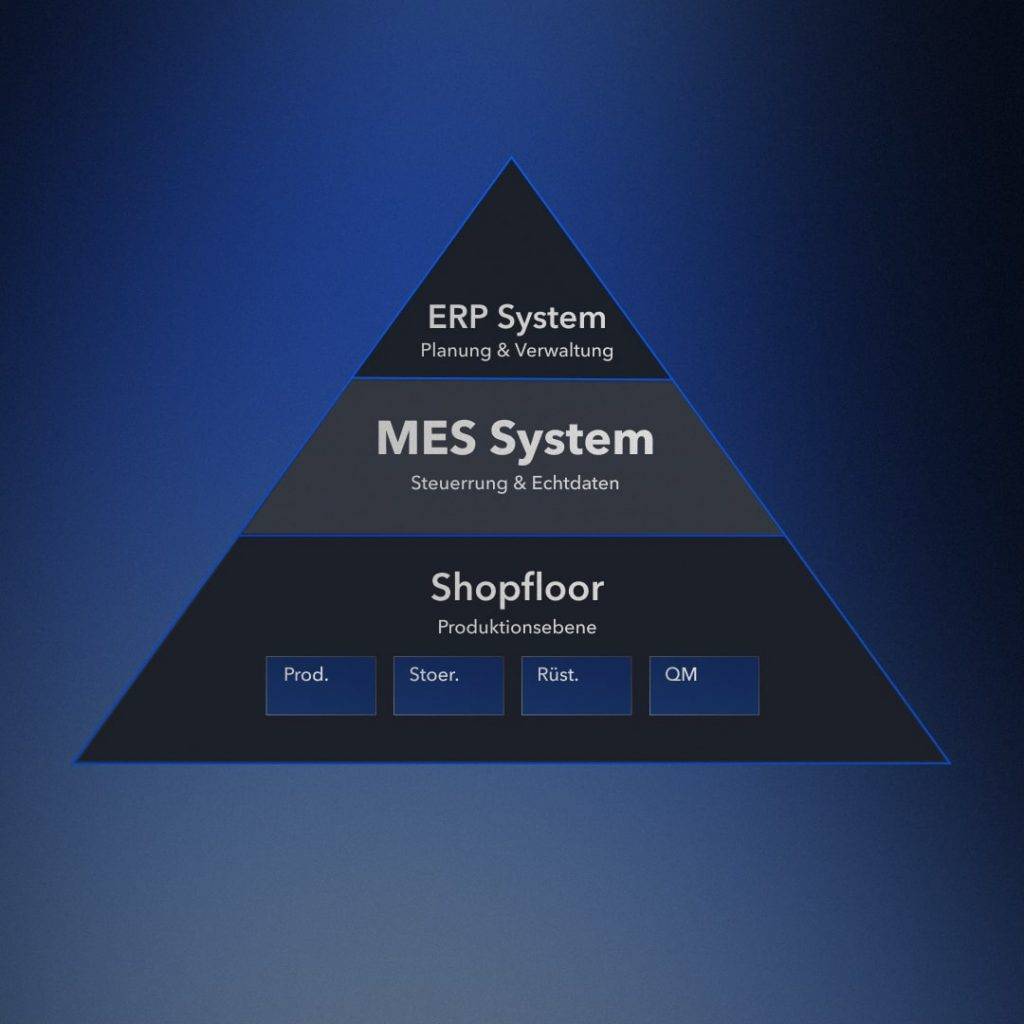

Ein MES System (Manufacturing Execution System) bildet die zentrale Schnittstelle zwischen Produktionsplanung und Shopfloor. Es sorgt dafür, dass Fertigungsprozesse in Echtzeit überwacht, gesteuert und dokumentiert werden. Produktionsdaten, Maschinenzustände und Betriebsinformationen werden von einer MES Software zusammengeführt, analysiert und für fundierte Entscheidungen nutzbar gemacht.

So schafft ein MES System Transparenz in der Produktion, reduziert Stillstände und unterstützt Unternehmen dabei, ihre Fertigungsleistung nachhaltig zu verbessern.

Manufacturing Execution System (MES) im Überblick

Was ist ein MES System?

Ein MES System verbindet die operative Produktion mit der digitalen Steuerung eines Unternehmens. Es sorgt dafür, dass Fertigungsprozesse in Echtzeit sichtbar, steuerbar und nachvollziehbar werden. Maschinen, Anlagen und Mitarbeitende liefern laufend Daten, die zentral erfasst und ausgewertet werden.

In der Praxis unterstützt ein MES System Unternehmen dabei, Produktionsaufträge transparent abzuwickeln, Abweichungen frühzeitig zu erkennen und Prozesse gezielt zu optimieren. Produktionsstatus, Durchlaufzeiten, Stillstände oder Qualitätsinformationen stehen jederzeit aktuell zur Verfügung und bilden die Grundlage für fundierte Entscheidungen in der Fertigung.

MES System Definition

Ein Manufacturing Execution System (MES) ist eine Softwarelösung zur Steuerung, Überwachung und Dokumentation von Produktionsprozessen in Echtzeit. Es erfasst Produktionsdaten wie Auftragsstatus, Maschinenzustände, Mengen, Zeiten oder Qualitätsinformationen und stellt diese zentral für Analyse, Auswertung und Optimierung bereit.

Mehr Transparenz, Effizienz und Steuerbarkeit in der Fertigung

Warum sind MES Systeme in der Produktion wichtig?

Die Anforderungen an moderne Produktionsbetriebe steigen stetig: mehr Varianten, kürzere Lieferzeiten und höherer Kostendruck bei gleichzeitig steigenden Qualitätsansprüchen.

MES Systeme schaffen hier die notwendige Transparenz und Steuerbarkeit, indem sie Produktionsprozesse in Echtzeit sichtbar machen und gezielt unterstützen:

Transparenz: Aktueller Status von Aufträgen, Maschinen und Ressourcen jederzeit verfügbar

Schnelle Reaktionsfähigkeit: Stillstände, Abweichungen und Störungen werden sofort erkannt

Qualitätssicherung: Lückenlose Erfassung von Prozess- und Qualitätsdaten

Kostenkontrolle: Reduzierung von Ausschuss, Nacharbeit und ungeplanten Stillständen

Stabile Abläufe: Vergleichbare, messbare und reproduzierbare Produktionsprozesse

Kurz gesagt: Ein MES System macht Produktion messbar, steuerbar und kontinuierlich verbesserbar.

MES Software Funktionsweise

Wie funktioniert ein MES System?

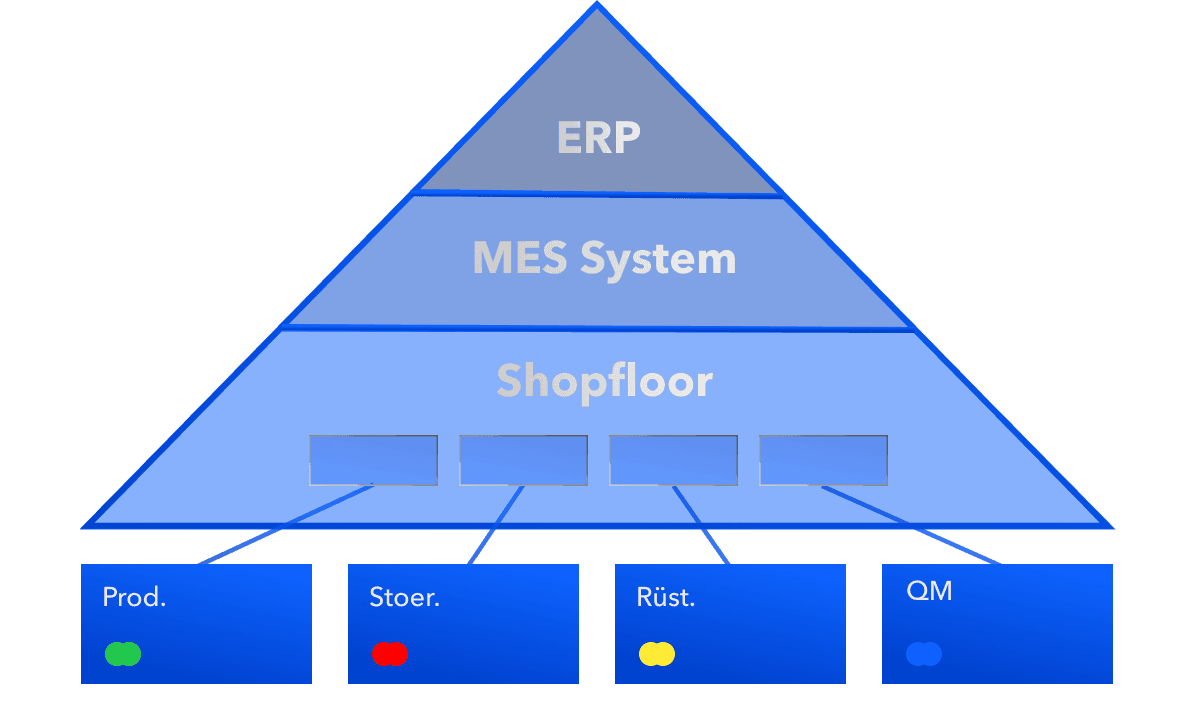

Ein MES System bildet die zentrale Ebene zwischen Shopfloor und übergeordneten IT-Systemen. Eine MES Software erfasst, verarbeitet und steuert Produktionsdaten in Echtzeit und macht Abläufe transparent, steuerbar und nachvollziehbar.

Die Grundlage bildet die kontinuierliche Datenerfassung direkt in der Produktion. Maschinen, Anlagen und Mitarbeitende liefern Informationen zu Aufträgen, Mengen, Zeiten, Zuständen und Qualitätsmerkmalen. Diese Daten werden im MES System gebündelt, ausgewertet und unmittelbar für Entscheidungen nutzbar gemacht.

Auf Basis dieser Echtzeitdaten unterstützt eine MES Production Software die operative Produktionssteuerung: Aufträge werden überwacht, Abweichungen früh erkannt und Prozesse gezielt angepasst. Gleichzeitig sorgt das System für eine lückenlose Dokumentation über den gesamten Fertigungsprozess hinweg.

Ergebnisse, Kennzahlen und Statusmeldungen stehen sofort für Analysen, Berichte und Optimierungen zur Verfügung. So entsteht ein geschlossener Regelkreis aus Datenerfassung, Auswertung und Steuerung.

Kurz zusammengefasst:

Daten erfassen (Maschinen & Mitarbeitende)

Daten zusammenführen (MES System)

Auswerten, Kennzahlen & Alarme erzeugen

Rückmeldung und Steuerung der Prozesse

MES Software

Welche Funktionen hat ein MES System?

Ein MES System (Manufacturing Execution System) bildet die zentrale Steuerungs- und Informationsschicht zwischen ERP-System und Shopfloor. Es sorgt dafür, dass Produktionsprozesse transparent, steuerbar und auswertbar werden. Moderne MES Software bündelt dabei alle relevanten Produktionsdaten in Echtzeit und stellt sie kontextbezogen zur Verfügung.

Produktionsüberwachung

Eine der Kernfunktionen eines MES Systems ist die kontinuierliche Überwachung und Steuerung der laufenden Produktion. Produktionsaufträge, Maschinenzustände und Prozessfortschritte werden in Echtzeit erfasst und visualisiert.

Read more

Die MES Production Software ermöglicht es, Abweichungen sofort zu erkennen, gezielt einzugreifen und Produktionsabläufe flexibel anzupassen. Dadurch lassen sich Stillstände reduzieren und Durchlaufzeiten optimieren.

Production Data Acquisition

Ergänzend zur MDE erfasst die Betriebsdatenerfassung (BDE) alle auftrags- und personalbezogenen Produktionsdaten. Dazu zählen beispielsweise Start- und Endzeiten von Arbeitsgängen, Mengenrückmeldungen oder Auftragsstatus.

Read more

Ein MES System verknüpft diese Informationen mit den Maschinendaten und schafft damit eine vollständige Sicht auf den Produktionsprozess – von Auftrag bis Fertigmeldung.

Machine Data Acquisition

Die Maschinendatenerfassung (MDE) ist ein zentraler Bestandteil einer modernen MES Production Software. Maschinen liefern automatisch Informationen zu Laufzeiten, Stillständen, Störungen oder Ausschussmengen.

Read more

Diese Daten werden durch die MES Software direkt verarbeitet und bilden die Grundlage für Transparenz auf Maschinen- und Linienebene. So entsteht ein objektives Bild der tatsächlichen Produktionsleistung – unabhängig von manuellen Rückmeldungen.

Quality Management

Ein weiteres zentrales Einsatzgebiet eines MES Systems ist das Qualitätsmanagement. Prüfmerkmale, Messwerte und Qualitätsabweichungen werden direkt im Produktionskontext erfasst und dokumentiert.

Read more

Enable your workers to carry out an online inspection during production directly in SAP. Similar to the QM inspection lot, the worker records the quantitative and qualitative inspection characteristics on the X-NetMES terminal. A dynamic workflow, derived from the SAP inspection plan, guarantees an ergonomic process.

Our MES offers the option of connecting digital measuring equipment. There are also interfaces to complex testing systems.

Rückverfolgbarkeit und Dokumentation

Ein MES System stellt die lückenlose Rückverfolgbarkeit von Materialien, Chargen und Prozessschritten sicher. Alle relevanten Produktions- und Qualitätsdaten werden nachvollziehbar dokumentiert.

Read more

Die MES Production Software liefert damit eine fundierte Entscheidungsgrundlage für Produktionsleitung und Management und unterstützt eine kontinuierliche Prozessoptimierung.

Analyse, Kennzahlen und Reporting

Auf Basis der erfassten Maschinen- und Betriebsdaten bietet eine MES Production Software umfangreiche Analyse- und Reporting-Funktionen. Kennzahlen wie OEE, Verfügbarkeit oder Ausschussquoten lassen sich automatisiert berechnen und darstellen.

Read more

Die MES Software liefert damit eine fundierte Entscheidungsgrundlage für Produktionsleitung und Management und unterstützt eine kontinuierliche Prozessoptimierung.

MES Systeme in der Praxis: Vom Konzept zur produktiven Umsetzung

Der größte Hebel eines MES Systems liegt nicht allein in der Funktionstiefe, sondern in der nahtlosen Integration in die bestehende Produktions-IT.

In der Praxis zeigt sich jedoch schnell, dass der tatsächliche Nutzen eines MES Systems nicht allein von den Funktionen abhängt, sondern vor allem davon, wie konsequent und nahtlos das System in die bestehende Produktions-IT integriert ist.

Viele Unternehmen stehen dabei vor der Herausforderung, ein leistungsfähiges MES System einzuführen, ohne zusätzliche Komplexität, Medienbrüche oder redundante Datenstrukturen zu schaffen. Genau hier unterscheiden sich klassische MES Software-Lösungen von modernen, integrierten MES Systemen, die speziell für den produktiven Einsatz in der Fertigung entwickelt wurden.

MES System Vorteile in der Praxis - Beispiel:

Das MES System der IGH Infotec AG: MES-Software - Vorteile für die Produktion

Mit dem MES System der IGH Infotec AG erhalten Unternehmen eine leistungsstarke Lösung zur digitalen Steuerung und Überwachung ihrer Produktionsprozesse. Das System verbindet Transparenz auf dem Shopfloor mit klaren Strukturen für Planung, Analyse und Optimierung – praxisnah, skalierbar und auf industrielle Anforderungen ausgelegt.

Transparente KPI-Analyse im MES System

Eine moderne MES Software ermöglicht die zentrale Analyse aller relevanten Produktionskennzahlen in Echtzeit. Über übersichtliche Dashboards lassen sich KPIs visualisieren, Details per Drill-down analysieren und individuelle Ansichten für unterschiedliche Rollen konfigurieren – vom Werker bis zum Management. So werden Produktionsabweichungen frühzeitig erkannt und fundierte Entscheidungen datenbasiert getroffen.

KPI

The Data in a

System gebündelt

Ein MES System führt alle produktionsrelevanten Daten in einem zentralen System zusammen. Maschinen-, Betriebs-, Qualitäts- und Prozessdaten stehen konsistent und in Echtzeit zur Verfügung. Dadurch entsteht eine durchgängige Datenbasis ohne Medienbrüche. Für maximale Transparenz entlang der gesamten Wertschöpfungskette.

Produktions-Painpoints mit MES Software frühzeitig erkennen

Mit einer MES Software lassen sich kritische Zustände und Abweichungen in der Produktion frühzeitig identifizieren. Störungen, Stillstände oder Qualitätsprobleme werden sofort sichtbar, noch bevor sie zu größeren Auswirkungen führen. Das ermöglicht kurze Reaktionszeiten, proaktives Handeln und eine nachhaltige Optimierung der Produktionsprozesse.

Hohe Skalierbarkeit durch modularen MES-Aufbau

MES Production Software sollte modular aufgebaut sein und mit den Anforderungen der Produktion wachsen. Funktionen lassen sich schrittweise erweitern – von der Produktionsüberwachung über MDE und BDE bis hin zu Qualitäts- und Analysemodulen. Diese Flexibilität sorgt dafür, dass das MES System sowohl für einzelne Fertigungsbereiche als auch für komplexe Produktionsumgebungen geeignet ist.

MES System ohne Schnittstellen

Ein moderne MES Software sollte im Optimalfall nahtlos in das ERP-System integriert werden. Statt komplexer Schnittstellen profitieren Unternehmen von einem durchgängigen Datenfluss zwischen Planung, Produktion und Auswertung. Beispielsweise ein SAP MES, das direkt im ERP verankert ist, ermöglicht eine konsistente Datenbasis in einem einzigen System und reduziert Integrations- sowie Wartungsaufwand deutlich.

Warum das MES System der IGH Infotec AG?

Nahtlos integriert statt angebunden:

Das MES System der IGH Infotec AG ist tief in bestehende ERP-Strukturen integrierbar und ermöglicht einen durchgängigen Datenfluss ohne komplexe Schnittstellen.

Praxisnah für die Produktion entwickelt:

Funktionen und Prozesse orientieren sich konsequent an realen Anforderungen aus Fertigung und Shopfloor – nicht an theoretischen Modellen.

Messbare Transparenz in Echtzeit:

Produktionskennzahlen, Zustände und Abweichungen stehen unmittelbar zur Verfügung und bilden die Grundlage für fundierte Entscheidungen und kontinuierliche Optimierung.

Erfahren Sie, wie ein MES System Produktionsprozesse messbar effizienter macht.

In unseren Events zeigen wir anhand realer Anwendungsfälle (Live Demos, Praxisbeispiele und Q&A), wie Unternehmen mit einem MES System Transparenz schaffen, Prozesse optimieren und ihre Produktion nachhaltig steigern.

MES System FAQ

Frequently asked questions

Hier finden Sie häufig gestellte Fragen rund um das Thema MES System. Erfahren Sie, wie

Was ist ein Manufacturing Execution System (MES)?

Ein Manufacturing Execution System (MES) ist ein IT-System, das Produktionsprozesse in Echtzeit überwacht, steuert und dokumentiert. Es verbindet die operative Ebene der Fertigung mit den übergeordneten Planungssystemen und sorgt dafür, dass Aufträge, Maschinen, Materialien und Mitarbeiterdaten transparent zusammengeführt werden. MES Systeme schaffen damit die Grundlage für eine effiziente, datenbasierte Produktion.

Welche Aufgaben hat eine MES Software in der Produktion?

Eine MES Software erfasst und verarbeitet Produktionsdaten direkt am Shopfloor. Dazu gehören unter anderem die Überwachung von Aufträgen, die Erfassung von Maschinen- und Betriebsdaten, die Qualitätskontrolle sowie die Rückverfolgbarkeit von Produkten und Materialien. Ziel ist es, Produktionsabläufe transparenter zu machen, Abweichungen frühzeitig zu erkennen und Prozesse kontinuierlich zu optimieren.

Was ist der Unterschied zwischen einem MES System und ERP-Systemen?

ERP-Systeme planen und verwalten Geschäftsprozesse auf betriebswirtschaftlicher Ebene, während ein MES System die operative Umsetzung in der Produktion übernimmt. Eine MES Production Software arbeitet deutlich näher an Maschinen und Mitarbeitern und liefert Echtzeitdaten aus der Fertigung. Beide Systeme ergänzen sich: Das ERP plant, das MES setzt um und meldet aktuelle Produktionsdaten zurück.

Für welche Unternehmen und Branchen sind MES Systeme sinnvoll?

MES Systeme eignen sich besonders für produzierende Unternehmen mit komplexen Fertigungsprozessen, hohen Qualitätsanforderungen oder Bedarf an Transparenz in Echtzeit. Typische Einsatzbereiche sind unter anderem Maschinen- und Anlagenbau, Automotive, Metallverarbeitung, Kunststoffindustrie sowie die Serien- und Variantenfertigung. Überall dort, wo Produktionsprozesse digital gesteuert und optimiert werden sollen, bietet ein Manufacturing Execution System einen klaren Mehrwert.